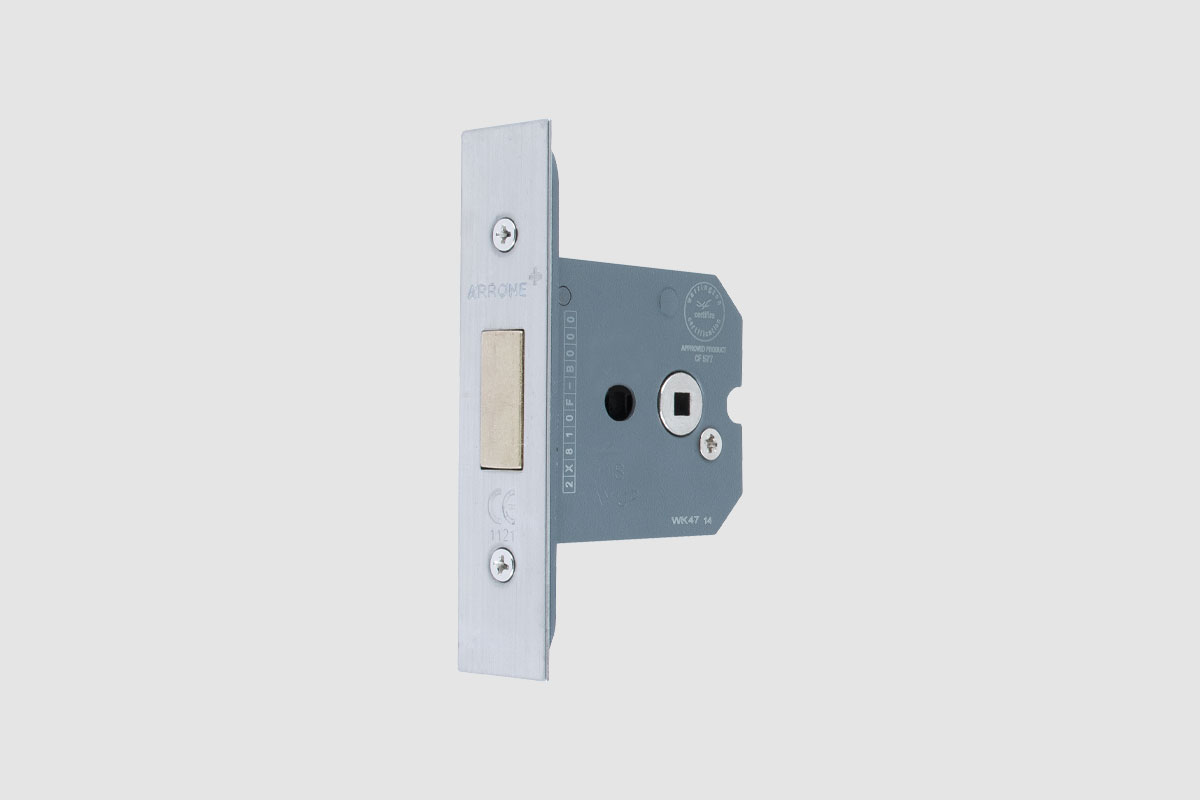

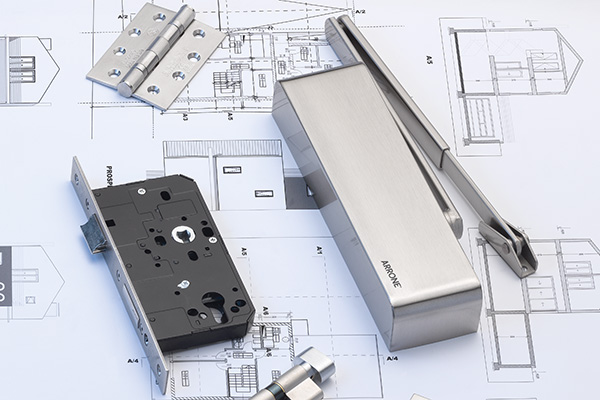

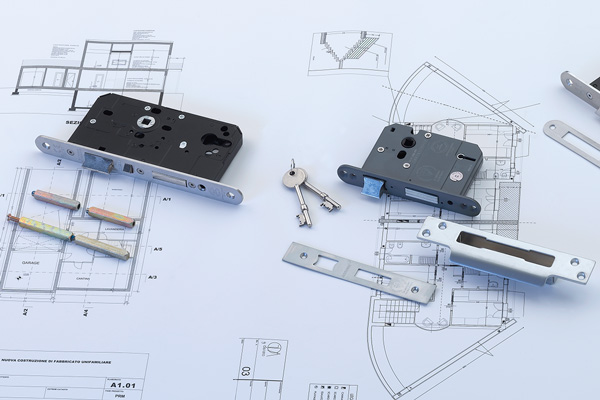

BS EN 12209:2003 – Mechanical Operated Locks, Latches and Locking Plates

This standard specifies requirements and test methods for the durability, strength, security, and function of mechanically operated locks and latches and their locking plates for use in doors, window doors, and entrance doors in buildings. The ARRONE range of locks has been successfully type tested to all the requirements of BS EN 12209:2016. The classification achieved is given for each lock separately.

11-Digit Coding System

The ARRONE range of locks is manufactured to the highest engineering standards and designed to offer a high price/performance ratio. They have been successfully type tested to all the requirements of BS EN 12209:2016. The classification achieved is given for each lock separately.

BS EN 12209:2003 classifies door furniture using an 11-digit coding system.

Digit 1 – Category of Use

Three categories of use are identified:

Grade 1: low frequency of use by people with a high incentive to exercise care and a small chance of misuse, e.g. internal residential doors

Grade 2: medium frequency of use by people with some incentive to exercise care but where there is some chance of misuse, e.g. internal office doors

Grade 3: high frequency of use by public or others with little incentive to exercise care and with a high chance of misuse, e.g. public doors

Digit 2 – Durability

Twelve grades are identified with minimum figures for deadbolt and snib operation, and latch bolt operation with and without side load, as shown. The side load is applied to the latch bolt when it is being withdrawn.

| ↑ No. of operations | Increasing side load → | ||||

| Grade C | Grade H | Grade M | Grade S | Grade X | |

| Grade B | Grade G | Grade L | Grade R | Grade W | |

| Grade A | Grade F | ||||

Digit 3 – Door Mass and Closing Force

Nine grades are identified with maximum figures for closing force at various door masses as shown.

Note: closing force is from a standing start, i.e. fully extended latch bolt in contact with striking plate at start of test.

| Maximum closing force | up to 100 kg | Door mass up to 200 kg | above 200 kg |

| 15 N | grade 7 | grade 8 | grade 9 |

| 25 N | grade 4 | grade 5 | grade 6 |

| 50 N | grade 1 | grade 2 | grade 3 |

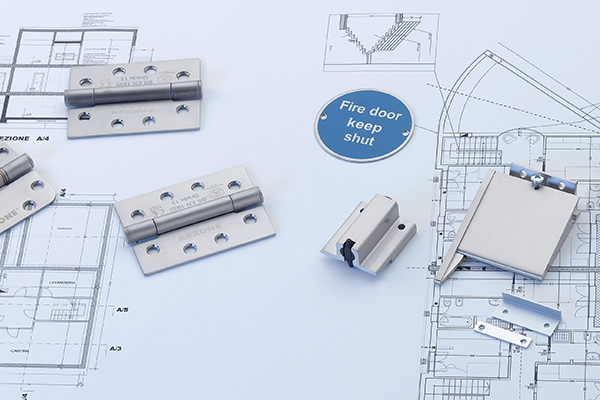

Digit 4 – Fire Resistance

Two grades are identified:

Grade 0: not approved for use on fire/smoke door assemblies

Grade 1: suitable for use on fire/smoke door assemblies tested to BS EN 1634-1 etc.

Digit 5 – Safety

No requirement, but note: A lock or latch conforming to this standard can, at the same time, also be part of an exit device conforming to BS EN 179:2008 or BS EN 1125:2008.

Digit 6 – Corrosion Resistance

Eight grades are identified with neutral salt-spray (NSS) corrosion resistance grades from BS EN 1670:2007, with and without temperature resistance as shown:

| Corrision resistance (NSS) | Temperature resistance No requirement | Temperature resistance -20 ºC to +80 ºC |

| 240 hours | grade D | grade G |

| 96 hours | grade C | grade F |

| 48 hours | grade B | grade E |

| 24 hours | grade A | |

| No requirement | grade 0 |

Digit 7 – Security and Drill Resistance

Seven grades are identified with minimum figures for requirements relating to physical attack, with or without drilling of the lockcase, as shown:

| Increasing resistance to attack | No drilling requirement | Drilling requirement |

| grade 6 | grade 7 | |

| grade 4 | grade 5 | |

| grade 3 | ||

| grade 2 | ||

| grade 1 |

Digit 8 – Field of Door Application

Fifteen grades are identified for differing applications – hinged or sliding doors with rim or mortice locks with either keyless egress from inside or key locking from both sides. The grading determines which application is appropriate. In addition, there is a requirement that lock/latch should not be removable from outside or, for grades K to R, from inside using “standard” tools. Grades H and P require support for the lockcase when installed.

Digit 9 – Type of Key Operation and Locking

Nine grades are identified for differing types of key operation. The grading determines how the lock is assessed for deadlocking requirement as shown. In addition, there is a maximum key torque operating requirement of 1.5 Nm and a minimum key strength requirement of 2.5 Nm.

Grade 0: not applicable

Grade A: cylinder lock or latch; manually locking

Grade B: cylinder lock or latch; automatically locking

Grade C: cylinder lock or latch; manually locking with intermediate locking

Grade D: lever lock or latch; manually locking

Grade E: lever lock or latch; automatically locking

Grade F: lever lock or latch; manually locking with intermediate locking

Grade G: lock or latch without key operation; manually locking

Grade H: lock without key operation; automatically locking

Digit 10 – Type of Spindle Operation

Five grades are identified:

Grade 0: lock without follower

Grade 1: lock with sprung lever or knob

Grade 2: lock with light unsprung lever

Grade 3: lock with heavy unsprung lever

Grade 4: lock with manufacturer’s own specification furniture

Digit 11 – Key Identification

Nine grades are identified relating to the number of differs and levers. Grade 0 relates to a latch with no locking action:

| ↑ No. of differ | No. of levers → | ||||||||

| grade H | |||||||||

| grade F | grade G | ||||||||

| grade D | grade E | ||||||||

| grade B | grade C | ||||||||

| grade A | |||||||||

| grade 0 | |||||||||

Source: Door and Hardware Federation (DHF) Best Practise Guide – Mechanically operated locks, latches and locking plates – BS EN 12209