Roller Multipoint Adjustment Instructions

Required Tools

A 4 mm or 5/32″ hex wrench is required

Introduction

This instruction applies to HOPPE HLS® 9000 and HLS® 2000 Roller Multipoint locking systems. HOPPE Roller Multipoint locks feature adjustability to provide optimal weather seal compression. Each Roller lock point has an adjustment cam that pivots about an eccentric axis. This allows for +/- 1 mm adjustments that provide additional weather seal compression or improved gear operation.

Making the Adjustment

- Open the door that features the Roller Multipoints and locate a Roller lock point. There are multiple Roller lock points in a locking system.

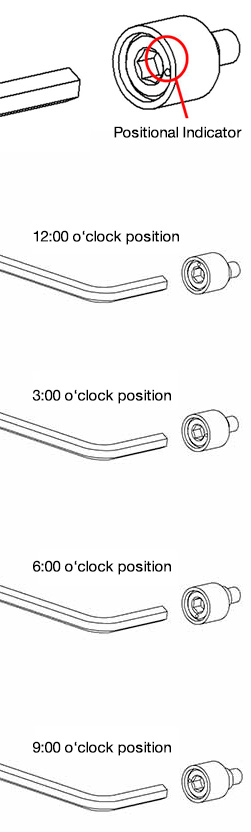

- On the face of the Roller lock point, locate the positional indicator. This small dot indicates the current positional setting of the Roller cam.

| A. A 9:00 o’clock position indicates the leftmost position. | |

| B. A 3:00 o’clock position indicates the rightmost position. | |

| C. A 6:00 o’clock position indicates the lowest roller position. | |

| D. A 12:00 o’clock position indicates the highest roller position. |

- Insert the hex wrench into the Roller cam and turn to move the positional indicator to the desired position. Turn the positional indicator toward the hinge side of the door to increase weather seal compression. The hinge side of the door is the side from which the hinges are visible when the door is closed. Turn the positional indicator away from the hinge side of the door to decrease weather seal compression.

- Repeat the adjustment for the remaining Roller lock points as desired.

- Close the door and engage the Roller Multipoints to test the adjustments.

- Adjustments may result in over-compression of the weather seal causing difficult lock operation. Re-adjust Rollers to reduce weather seal compression when lock operation is undesirable.