HOPPE’s Operational Guarantee

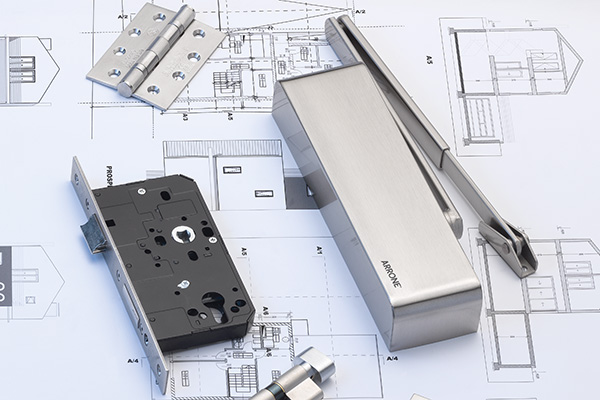

Our architectural fittings are extensively tested for lasting, flawless function – based on practice on the product carrier. That’s why we offer a 10-year guarantee on the mechanical operation of our door fittings and window handles.

10-year guarantee on the mechanical operation

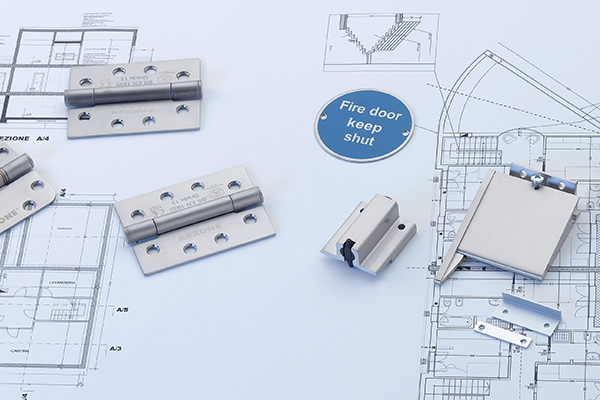

According to HOPPE, a brand-name product keeps its promise of quality to the enduser.

Our 10-year guarantee on the mechanical operation of all door and window handles of the HOPPE brand underlines this commitment (please see “HOPPE Operational Guarantee Declaration”).

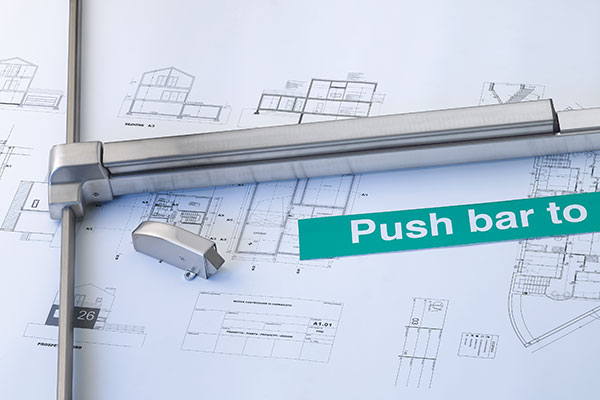

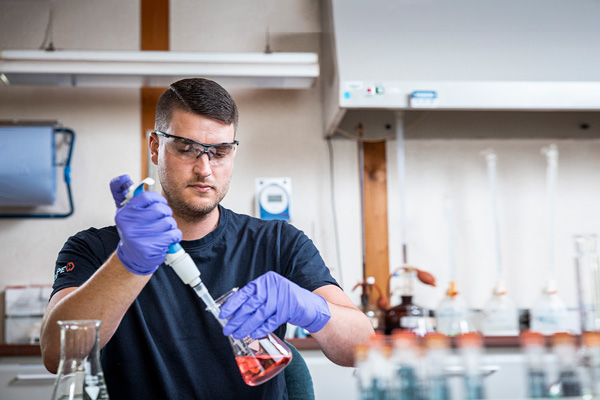

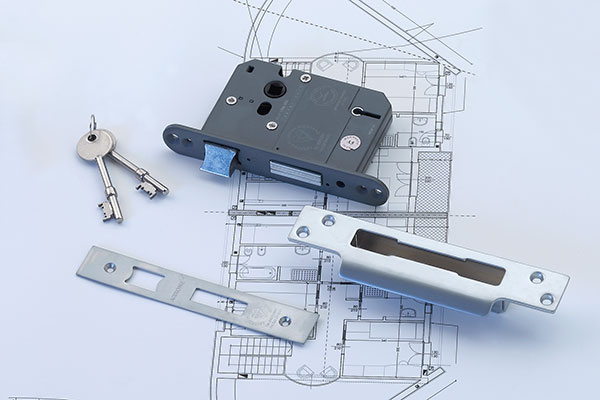

HOPPE realistically tests door and window handles in situation doors and windows.

Realistic load testing

HOPPE brand name products undergo numerous tests to ensure flawless operation. Static impact tests and durability tests are also made depending on the product type. These closely reflect the everyday knocks hardware has to take.

Whereas for DIN EN 1906 and RAL-GZ 607/9 hardware is tested in isolation, HOPPE also conducts operational tests when fitted on the door and window itself. This means that we test not just the function, but also the durability of the attachment between hardware and door or window.

Neither the door or window handle itself, nor any part of it, must become loose during the course of the test. They are then tested for their stability, ensuring perfect operation.

Still the Handle of excellence after 10 years of intense operational strain.